Hello forum,

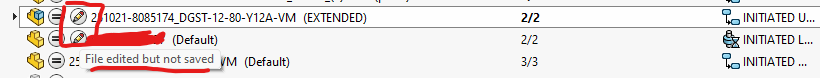

In your experience working with PDM&SW what are the causes for this error/issue to come up?

(please note my file is already checked-in; local & vault version are the same; there isn’t any in context or external relationships between this file and my assembly or other parts; and the part is not in flexible state)

In 95% of the times you can check it out, save, and check back in and the issue will be resolved, so I am less interested in how to fix it versus what caused this to begin with.

I also want to add that in documentation this message is slightly different, it says there “The local file is edited but not saved.”

Thanks,

1 Like

Check your dismissed errors/warnings in SW system options to make sure you’re not missing a message. Also, is this happening with newly created files or old files?

Newly created file.

I will investigate the dismissed errors, thanks.

My confusion is if a file is checked-in, isn’t it already saved (how can be edited if it’s checked-in and it has no external references)?

Or is there an argument that making a change & not actually hitting save but just checking-in can cause this issue? It’s possible that this has happened to this file.

I don’t use PDM but SolidWorks often throws that message for parts/assemblies that have had no change, I don’t have a link to provide but I’ve often seen VARs and Dassault employees refer to this as an issue with templates, but that is often used as an excuse more then an explanation.

Rather then digging deeper to find the root of the issue, they compare a new file with an old one and then conclude that because the new file on their side isn’t displaying the issue vs the old file displays the issue. It indicates to them “something differs in the file from the original” but they fail to dig deeper and tell you what differs.

Edit: There are indeed issues linked to old templates, they seem to have adressed the problem as it less recurrent now.

1 Like

I’ve definitely seen something like this happen as a result of templates. And not just part/assy/drawing templates. It was the whole reason my ‘Crusty Old Template Files’ gotcha post was created. Here’s what I wrote about it back in 2017:

“I have a set of test files for testing some custom add-ins I use with EPDM. I had a drawing file (of an assembly) that had been fully rebuilt, saved and closed. The next time I opened the drawing, the assembly file would be marked as needing to be saved in the EPDM task pane tree. If I opened the assembly file itself, it would not have the needs to be saved flag. The problem would go away if I deleted the BOM from the drawing. This BOM was created using our custom BOM template file which has some columns linked to custom properties of the model. If I added the standard BOM template included with SW 2017, and customized it exactly as our old template, the problem did not reoccur. So, the only explanation is that the crusty old template was causing the problem.”

2 Likes

Thanks for sharing that excerpt, def good info to have for older parts in future.

Do you know if there’s any difference between saving and checking-in versus just checking in - I never thought about this, but I am now wondering if it makes any difference. I guess I am always used to do a save anyways by habit, not sure if everyone follows this practice where I work or even if it matters.

I’m fairly certain that a check in will always save.

1 Like

Its changed (flagged as dirty) in memory when the part was loaded. There are a variety of reasons that can trigger it but mostly it just means the part was “rebuilt” when it loaded or sometime after. Since its read-only and not checked out, a save of the assembly will work but likely you see it again on load again.

Common causes:

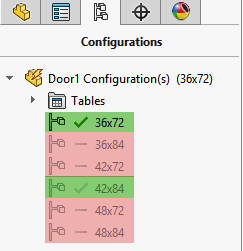

- Part has multiple configurations that are not rebuilt and your assembly uses one of them. This happens when the part was edited and you don’t rebuild all configurations.

The green configs are rebuilt, the red are not. Any assemblies using them will force them to rebuild on load and flag the file as dirty. Always rebuild all configurations and get the green checkmark on all.

- You opened a non-checked part from the assembly, poked around, edited a feature to review something, etc. This caused a rebuild and flagged the file in memory as dirty. If you close the part’s window it usually prompts to keep changes or discard (which reloads the file and should get rid of the dirty flag).

- Bugs. I’ve had some complex sheet metal parts that has multiple configurations and can’t get all configurations to the green check mark. This seems to be caused in the past by the unfold/fold commands or some combination of that and older files, hard to say exactly.

4 Likes

You just solved my issue! At least in this case I think number#1 (not all configs were rebuilt after part update) happened. Both of the parts with the pencil icon had configurations without rebuild mark.

Maybe I didn’t look deep enough, but to me this is a very important piece of information (given how much configurations are used) and I am surprised it’s not emphasized more in documentation or KB, or other resources I checked (there is info about check mark yes, but how it can trigger this “file edited but not saved” issue is not really mentioned).

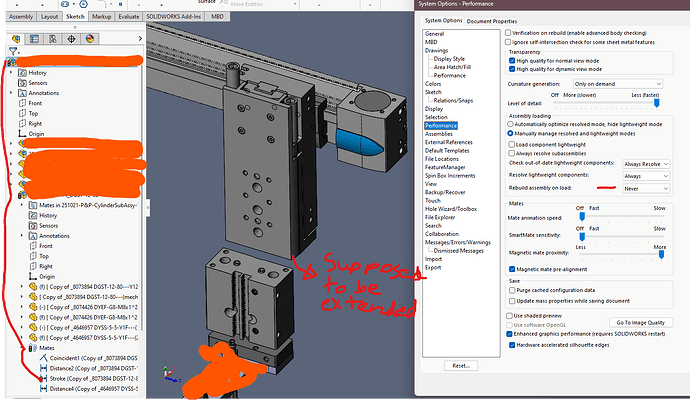

And actually to verify this, I intentionally set my system settings to never rebuild upon loading and it lead me rebuild icon to rebuild icon to exact feature that had to be rebuilt. Even though the part had the right configuration (Extended) it was being shown as retracted. As soon as I hit ctrl-B that cylinder jumps forward.

I must have modified that distance mate while in retracted config and checked-in right away without rebuilding the extended config.

2 Likes