Two each their own but aren’t you just complicating it by manually creating what the hole wizard already does internally? The hole wizard is just a hole feature and sketch driven pattern in one. Separating is out just means a larger tree to deal with and organize. We have panels with hundreds of holes for mounting various mechanical and electrical components so the tree is already large enough with 50+ holes wizard features.

IMHO yes, it does complicate things, and gives no performance or practical benefit other than they like it that way. As you said, whatever floats your boat.

Y’all seem to like the hole wizard a lot, so maybe I am using it wrong or didn’t get things set up right. Can you let me know what I need to change to make this actually useful? Mostly, I am putting in thru, untapped holes. If I need a tapped hole, then I am likely to use the hole wizard, but otherwise, I don’t find it any faster.

So, one of the reasons I don’t use the hole wizard is changing my hole size is harder in the hole wizard. If I have created a circle in a sketch, I just double click on the dimension to change the size, typing in the new size I need. For a hole wizard hole, I have to go redefine the feature to change the size.

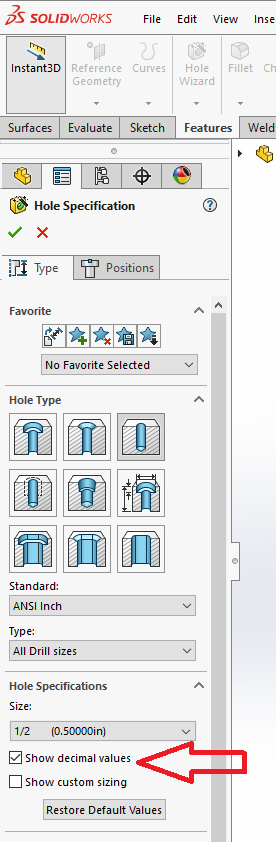

Also, finding the right size. Am I missing settings I need to change? For drilled holes, if I use the hole wizard, I get drill sizes. It’s not too bad for metric holes, but for inch holes, I have to go look up what the drill size that matches my decimal value is. And the list of drill sizes if you pick “all sizes” is crazy long.

The “close, normal, loose” fits for the screw clearances don’t always match what I want. I know that you can “show custom sizing” and change the hole value. You can also change the value of the hole size in the sketch. So, I put a hole in one of my parts to see what happened. I changed the value in the sketch to 6mm diameter. The feature tree still shows the hole at 3mm.

HW makes it easier to populate assemblies with hardware (faster rebuilds), have hole counts updated on hole call outs, call out standard drill sizes, on and on and on. I have run into people not calling out he correct hole sizes for PEMs, multiple hole sizes because the circles aren’t constrained correctly, etc which all adds up to remaking parts = $$$

CarrieIves

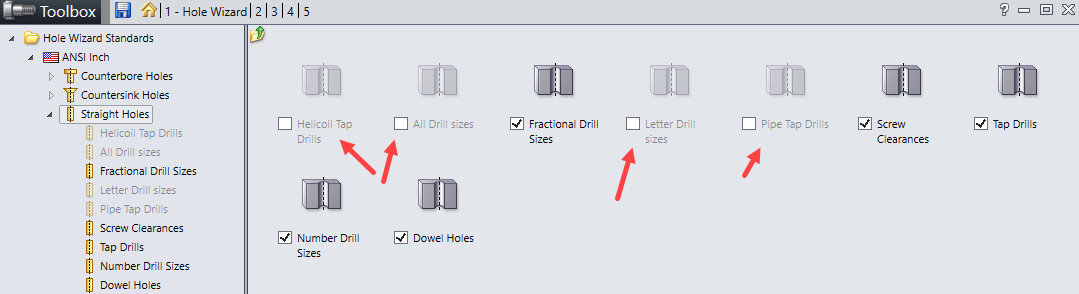

You can customize the Hole Wizard some. Go to Start and type “Toolbox” and launch the “Toolbox Settings” application.

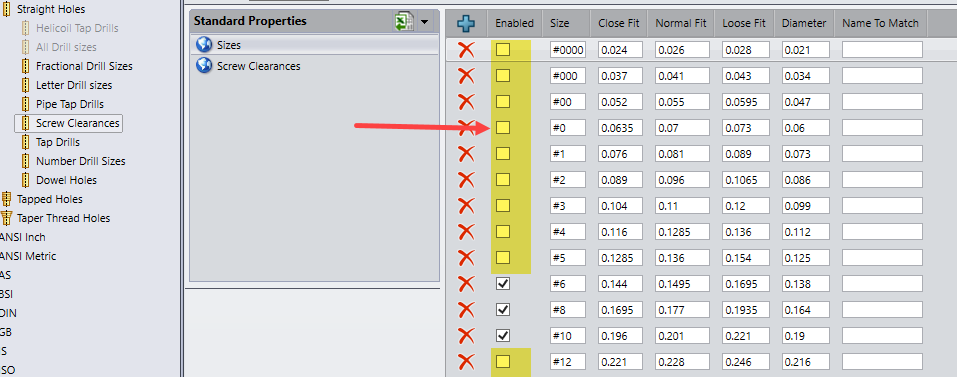

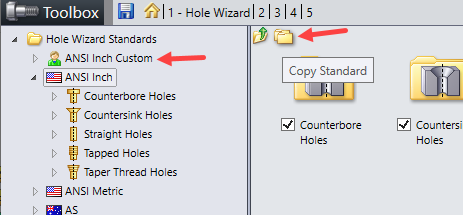

From there, the tab labeled “1” at the top is the hole wizard. You can go into a standard like “ANSI Inch” and turn on/off hole types and sizes.

You could limit “Screw clearance” holes to only the ones you have tooling for. You can also add new sizes.

You can also copy a standard and create sizes more in line with your company tooling and create custom sizes that aren’t “ANSI” standard.

Hole wizard is great but sometimes people tend to misuse it…

Just few weeks ago i had come across someone who put a “Tapped hole” using Hole Wizard on a plastic boss…

The hole was suppose to be a pilot hole for self tapping screw… ![]()

Regarding customize hole for Hole Wizard. If i share the file to others who dont have my hole wizard library, can they still edit the hole?

If you send your entire Hole Wizard to them, yes they will then have access to changing everything in it. If you share a link to yours and control the permissions then they will not be able to.

Has anyone found an easy way to update the hole call out file.

When I needed to have the 1-8 UNC THRU to read 1" -8 UNC THRU that was an easy fix. Add the " in the text file.

Now I need to have it read 1.000-8 UNC THRU. How do you get it to show the three decimal places?