Hi, I have a modelling question. I design a lot of parts for 3D printing. I tuned my printer well enough to achieve a dimensional accuracy of +/-0.025mm, which is a sufficient tolerance for most applications. However, some of the parts have to be coated with 2-3 layers of epoxy after printing for waterproofing, which can add up to 0.15mm to all dimensions - a very significant difference, which can easily throw off carefully designed fits with other parts. Therefore, I print my parts slightly smaller to account for epoxy coating, since it is a know and predictable value.

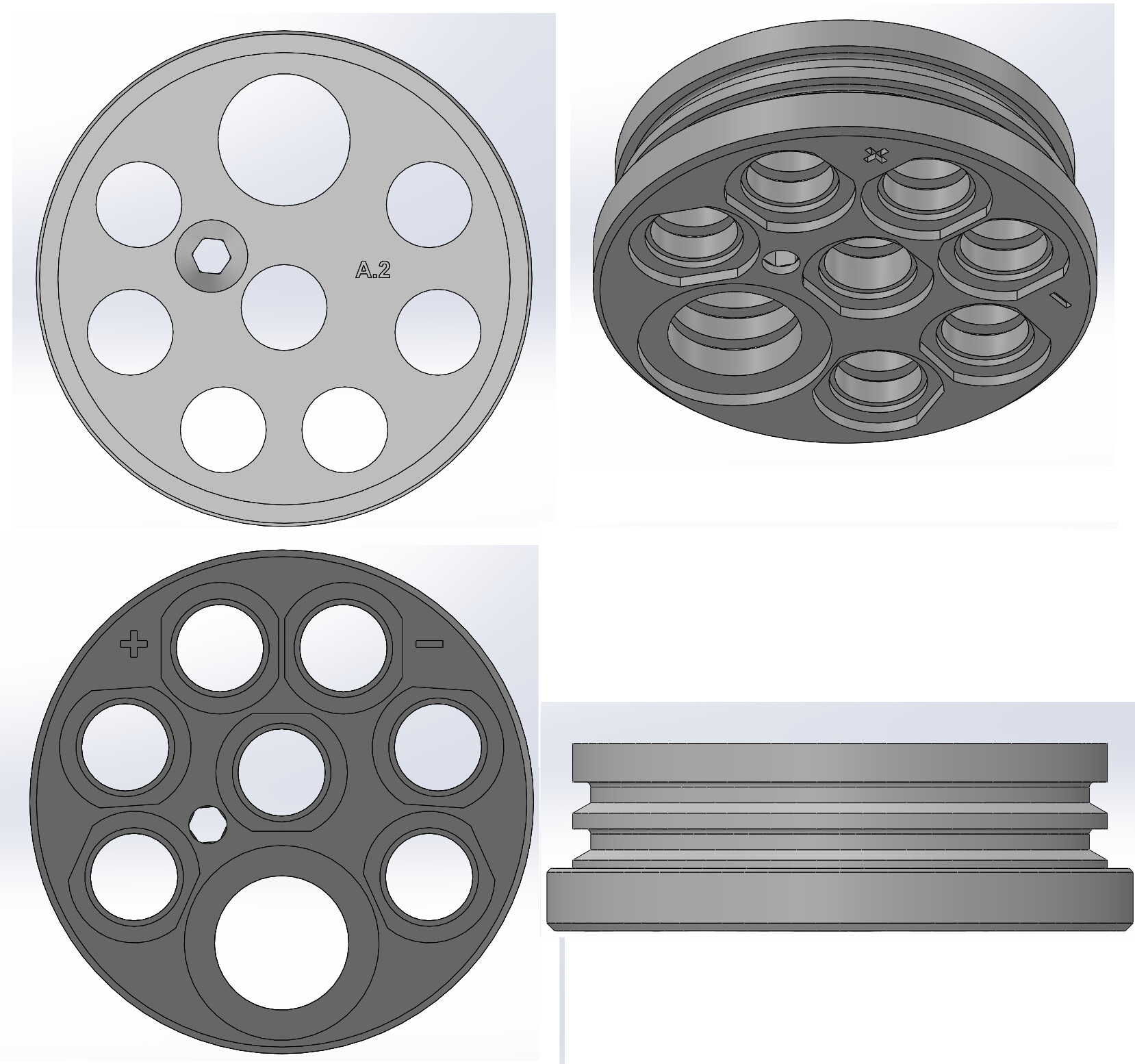

The issue is, Scale feature doesn’t do it right, because it shrinks the whole part, and while the outer features are scaled down more or less correctly, features such as holes become even smaller - the opposite of what I need. This is a quick illustration of what I mean:

image.png

There is only one feature that I know that does correct compensation - Move Face with Offset. The issue with this feature is that it requires faces to be selected; it cannot by applied to the whole body. This means this feature has to be baby-sited, every time something changes in the model, like new features are being added or deleted, the number of faces might change, so the feature needs updating (it either throws an error because old faces are missing, or says nothing when new faces appear, which is even worse). Sometimes even changing dimensions can change the number of faces in the model. It is very annoying to have to update this feature manually, and I already produced several defective parts because I forgot to do it.

Can someone offer an alternative, some other feature / combination of features that would be applied to the entire model automatically, without the need to baby-sit it?