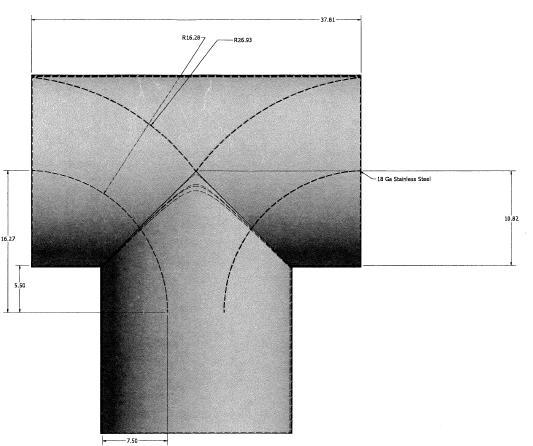

Can someone shed some light on the proper way to make these?

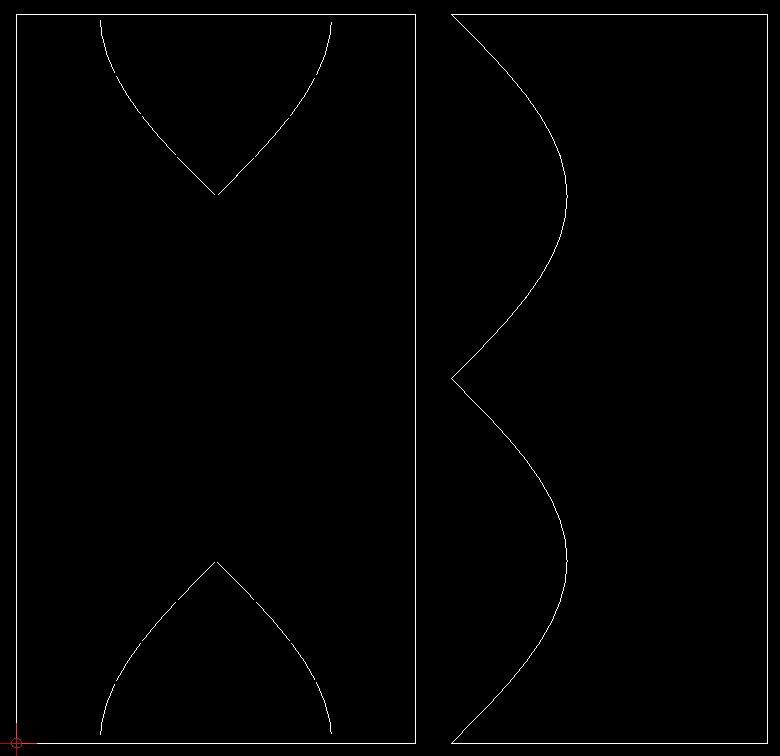

I normally create the sketch in Synch in sheetmetal with a 0.002 split then loft in ordered.

I create a solid OD sketch to normal cut, in this case the vertical extrusion.

How do you edit out the tapered edge or how else would you normalize the edge?

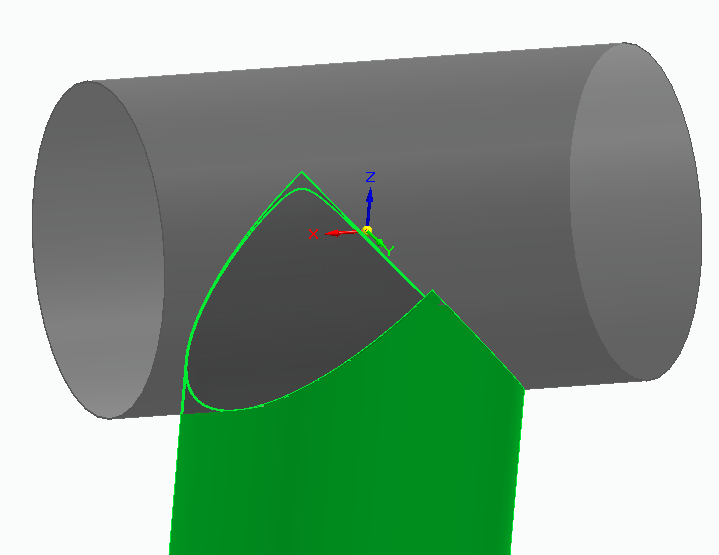

This particular part needs turning vanes which are cut the same way, the bottom vane was cut horizontally then vertically to meet at the junction.

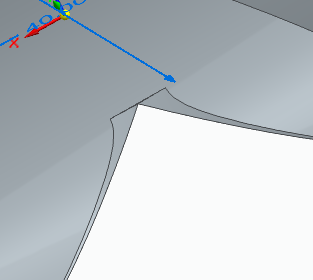

Here is what i came up with after a bunch of head scratching.

This was done with surfaces then thickened and the cuts turned out sharp.

I saw SW has a normalized cut tick option that works great, of course i cannot find it now, but i swear it was there… does SE have something similar?

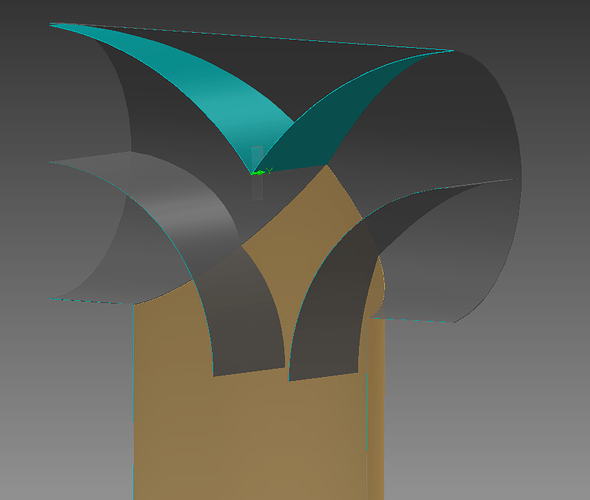

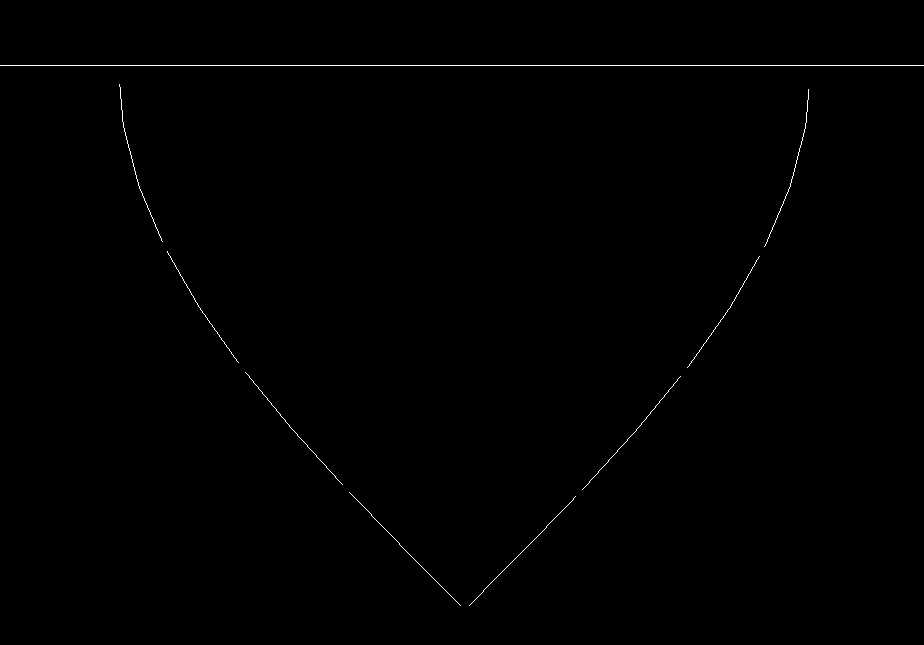

Last one for today…

How would you make interrupted cuts like these in SE prior to saving as dxf? Its left attached for rolling then cut out.

Currently I’m editing them in QCad then save as dxf.

Thanks.