I’m answering this from the standpoint of using multi-bodied parts for weldments. I’m not sure why you would use it for parts that are essentially assemblies.

If you have parts that you want to “Re-Use” or use often you can make templates of them and insert them.

How are you getting library parts into assemblies etc without inserting them? Maybe I’m not understanding this one.

Don’t understand this one either. Configurations in weldments work the same way they do everywhere else.

Not sure why. What is harder about making drawings from a multi bodied part versus an assembly or anything else?

Don’t understand this at all. You have one part.

Again, not sure why that would be. Everything is in one file. Errors are easily seen and rectified.

While you could do motion using multiple configurations, I’m really not sure why someone would use multi-body for an assembly…I mean it’s an assembly not a multi-bodoed part.

I don’t really agree with this statement. You have a single part that is treated as a single part. Modeling it as a single part is easier from start to finish from modeling thru ERP thru manufacturing.

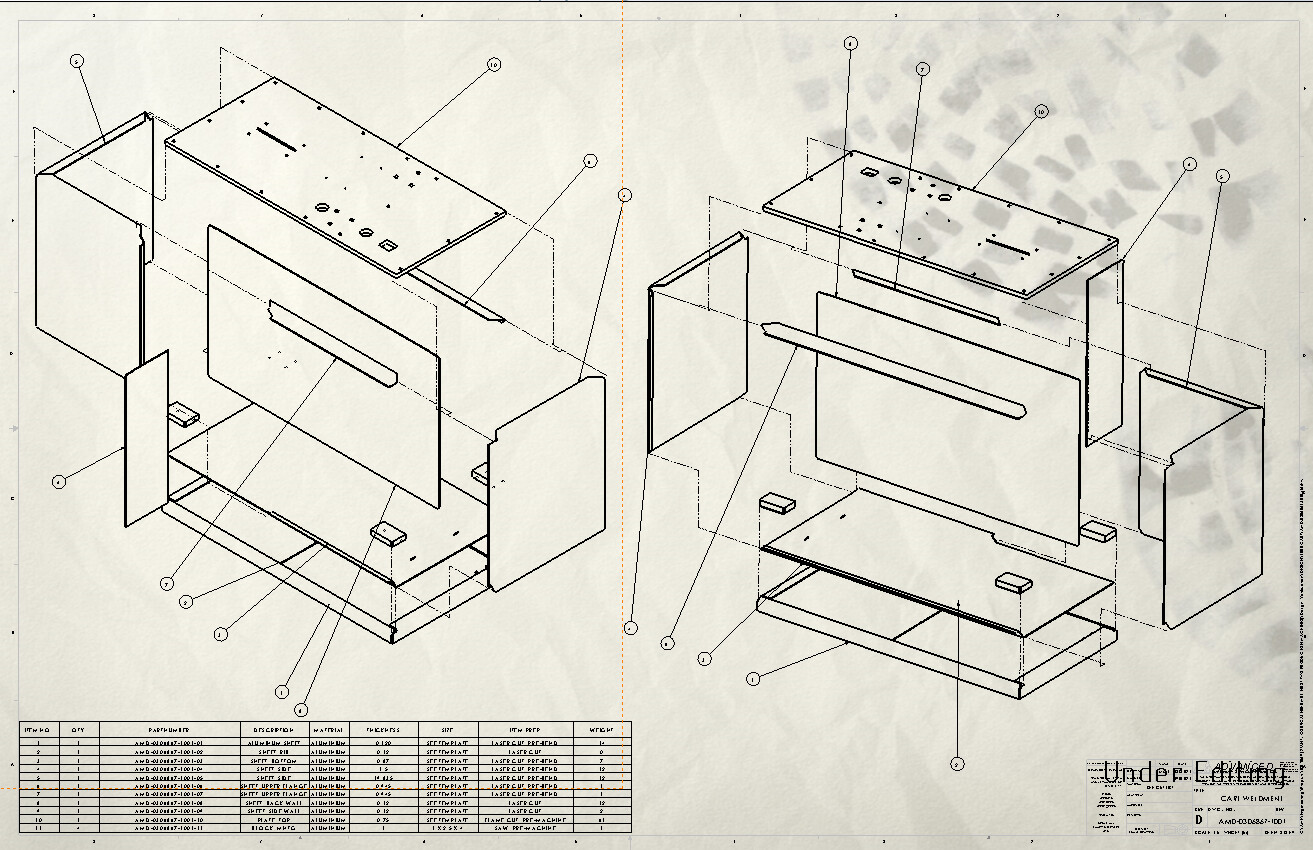

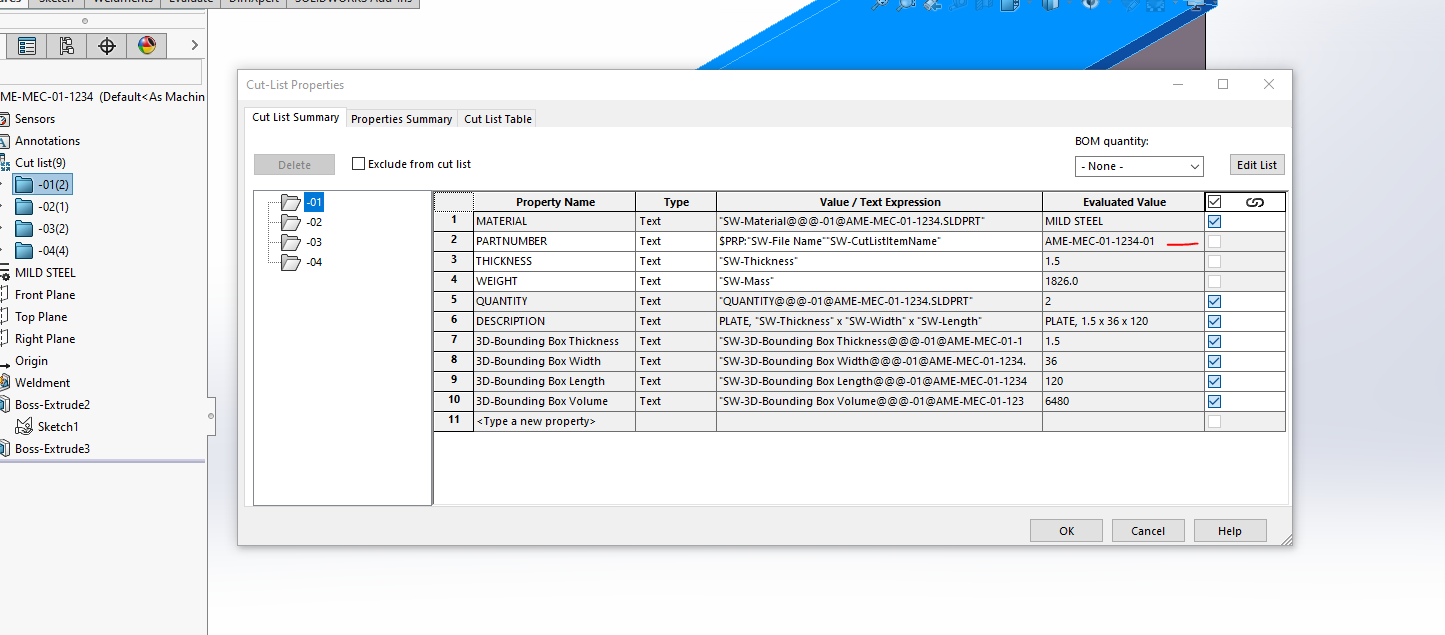

When I create a weldment all the properties are propagated via the weldment insertion. That keeps me from having to fill in nearly any custom properties which I would have to do individually for each part. I don’t have to mate them. If I want to I can create multiple parts from a single sketch. This is extremely helpful for weldments that have many individual parts that run thru an entire cross section. See the pic below. One sketch, two extrudes and I have an entire base, done. All the parts have many of the custom properties we use automatically populated.

All the changes for the entire cross section are contained inside a single sketch. Change the sketch, everything else updates. No opening multiple parts, hunting down which mate locates the part etc.

image.png

The vast majority of SW crashes I have happen in assemblies. In my opinion this is probably because of mates, rebuilds etc. Non of that exists in a multi-body part and I can honestly say I can’t remember but a few occasions on some really funky weldments where I’ve had SW crash in a weldment.

As to replacing assemblies with multi-bodies, I agree, that doesn’t make sense to me but if you’re making a weldment using multi-bodied parts is, at least IMO, significantly superior to assemblies.