Add upper management that keep changing “kits”.

One way is just parts in CAD, let ERP do the assembly.

Here is a strategy for you that you might be able to use, bnemec (although I know you’re opposed to virtual parts):

Use virtual components in your assembly.

At one point we were discussing the possibility of having a library part in our assembly that we would drag in, make virtual & modify to our gusto depending on the situation.

You can set up assemblies/parts with the correct custom properties so that the only thing you have to do, is to modify them.

It comes with all the salt that virtual parts come with though…

We’ve considered VCs in places similar to this, we thought there was merit but end up shooting it full of holes whenever we model real parts that exist in ERP as VCs. The final straw is maintaining the data. When the part is revised and the model needs updated, finding all the where used in CAD can become difficult. I have a SQL querry to find the assemblies that contain VCs who’s name contains the specified keyword (the part number for example) but there’s no control over the VC names. So we wind up without a where used search on the CAD side, we would find all the assemblies to update based on the ERP where used. That would be acceptable (assuming we could train users how to corrolate the ERP BOM structure to CAD structure) but the edit would still need to be done to every place that component is represented by a VC vs just updating one file that goes to a bunch of assemblies.

I’ve made a few “VC” just to fill the BOM.

Not really virtual, a part without model, just the required properties.

ie a hardware pack, ERP can change whatever in the pack and it won’t change the model.

How about this:

A promoted assembly with 2 configurations

One for your sub-assembly

One for your upper level assembly

Mated origin on origin.

The promoted assembly configs would serve the purpose you require for the sub-assembly and your upper level assembly, each calling out whatever’s required in the BOM. Any future modification would update itself across your products without having to reassign mates or whatevs

Oh, that might work combined with what I proposed with VCs:

You can make an empty config for you real part that you put in there (has all the custom properties you have).

You put the geometry for the parts into that assembly as a virtual parts that are excluded from the BOM.

You can modify the geometry as needed and you would not loose the custom properties.

I might look weird and have a bit of overhead in it, but you could modify the geometry as needed and have the part data, too.

Yes, geometry changes might be a pain in this case, but you would at least FIND it in PDM (because the part is in the same assembly…).

Neat ideas there, Frederick_Law .

This is what we do, for hinges, slides, and such. Works best for us.

Dwight

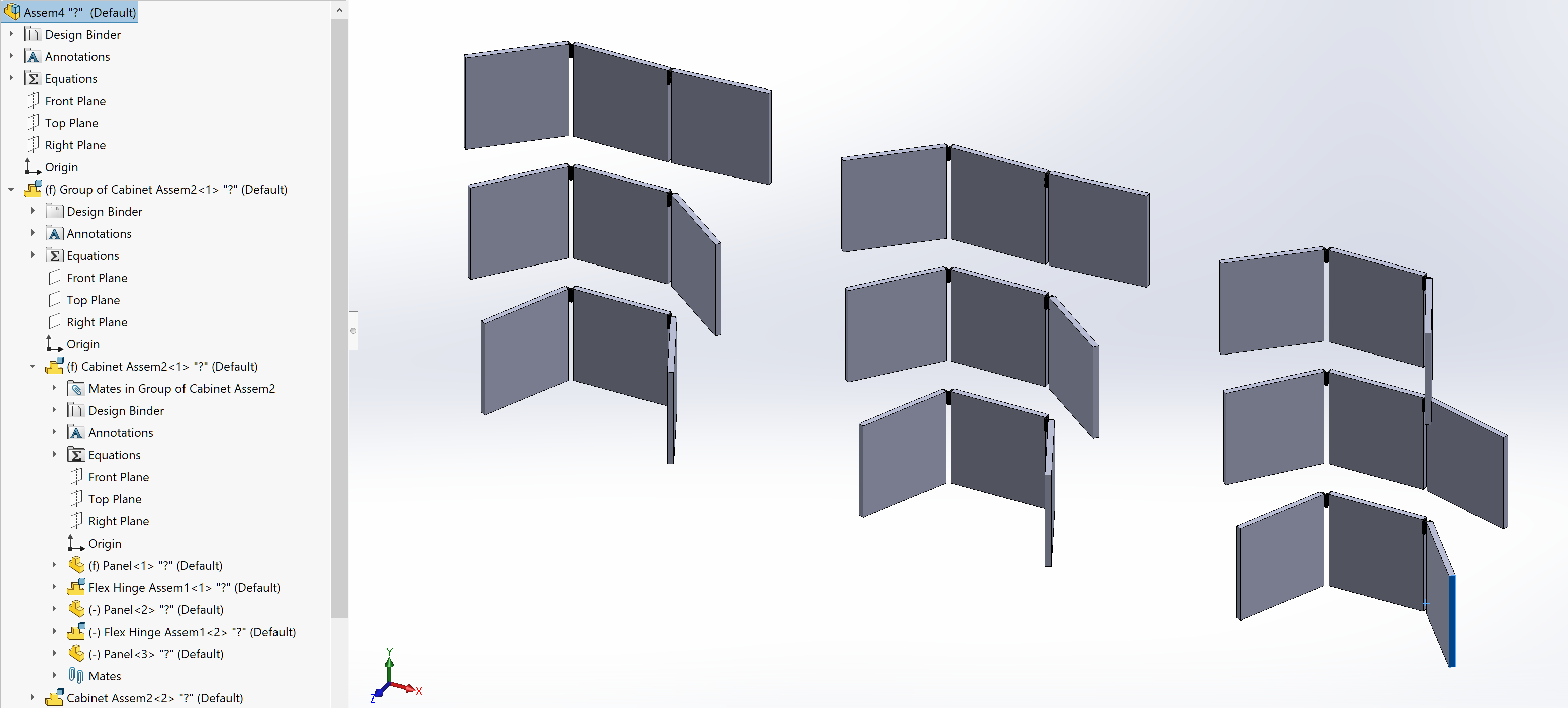

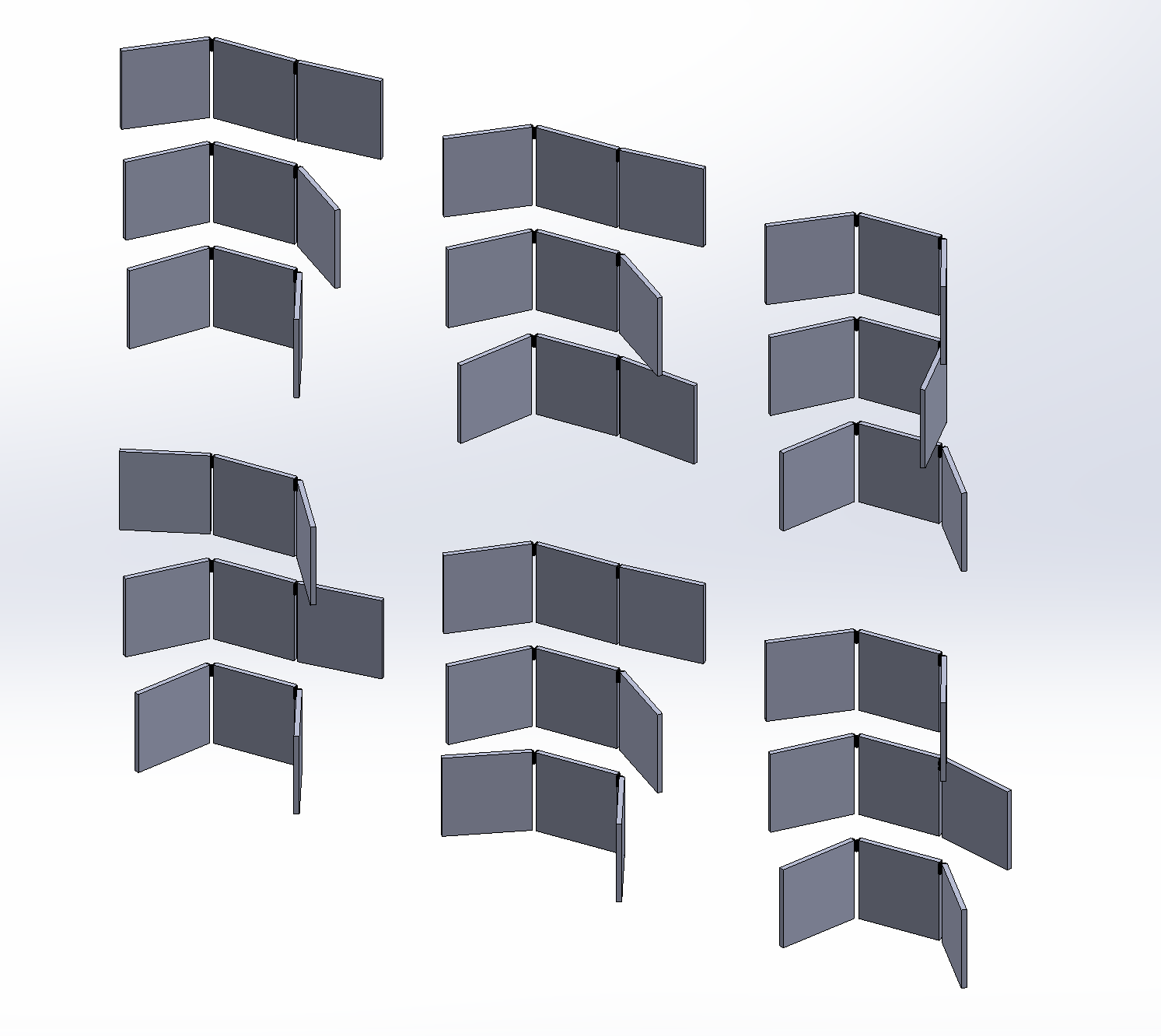

We used to do what you’re doing in the early days of SolidWorks (90’s-2000’s). We now build our hinges as an assembly with virtual parts for the pieces, then set to flexible. We’ve been using them nearly 10 years now and while buggy in the beginning, its a lot better today.

We’ve never been able to apply flexible more than one level down from the top assembly. Is that still the case with 2022?

I went to straight open/closed configurations on hinges, they are tough to do as “flexible” assemblies if you have more than one in an assembly, if you move the first one the others do not move since they are flexible as well. Not sure how you could get around this.

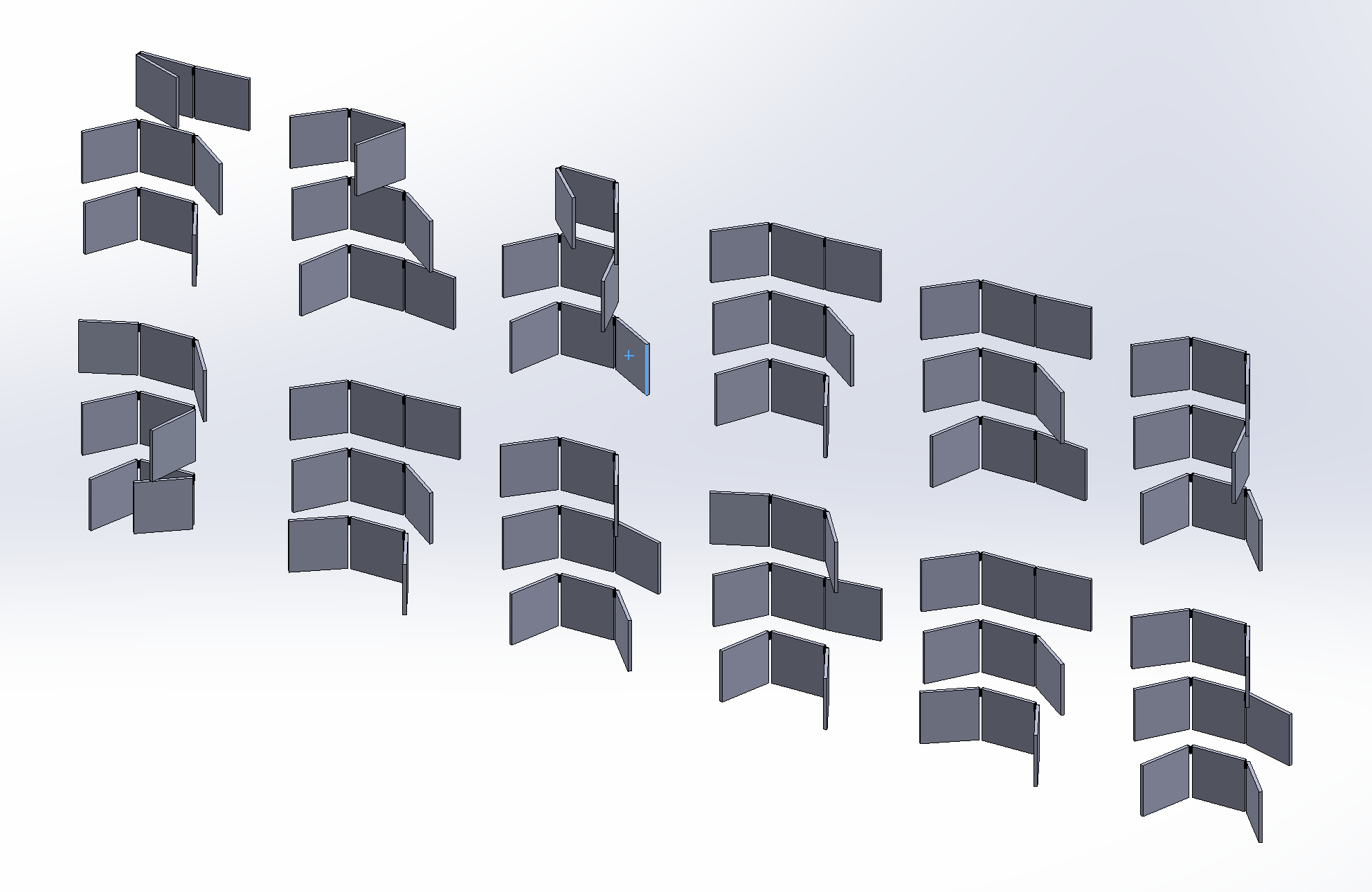

Flex-01.jpg

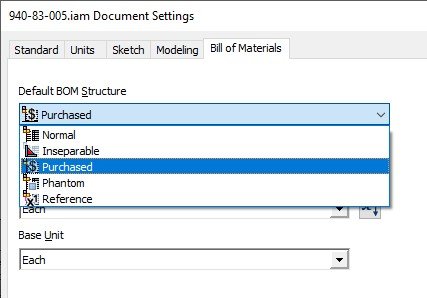

Sliding door wheel and stop kit.

This is a flexible assembly in IV.

The 4 “sub-assemblies” are mate so they can slide on same plane.

The wheels will mount on different width door. Stop on different length rail.

The assembly is set to “Purchased” in BOM. It will only show as one part in BOM, cannot get parts inside the assembly in BOM.

“Reference” will not show in BOM at all.

All the setting will show differently in BOM. This allow BOM manipulation in part and assembly level.

Use Solid Edge? Inventor maybe?

Simple flexible subs go at least three levels down in SolidWorks 2019. And more.

I’ve got a flexible assembly 3 levels deep and it is working fine. (2022 SP4.) Every sub in the chain has to be flexible.

image.png

I am a GIF. Click me!

I also use these quite frequently. I’ve noticed that flexibility can get turned off several levels deep in one document and not affect another document so it’s best to make sure everything is flexible on every level in every document if that makes sense.

I had a case where my top level model had something non-flexible 2 levels deep, but when I opened that sub-assembly directly, the flexibility settings were all correctly set to be flexible. Very odd but worth noting.

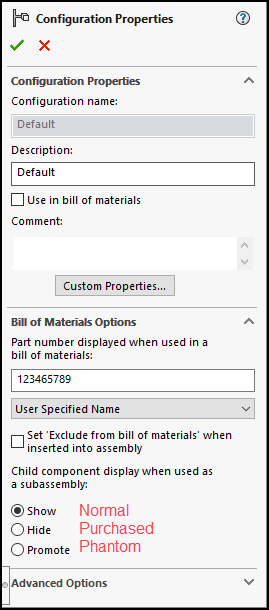

Nifty option names. The SolidWorks equivalent…I think:

Envelope would be the same as reference, however it’s set at the assembly tree as a component property rather than at the part/assy level…more of an override. I do like the IV names for them, makes it easier on the end users to pick the right setting.

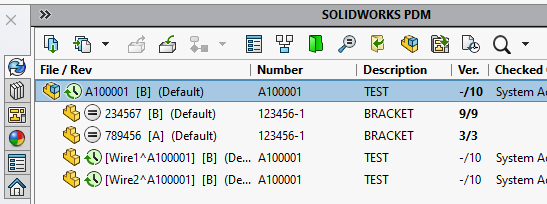

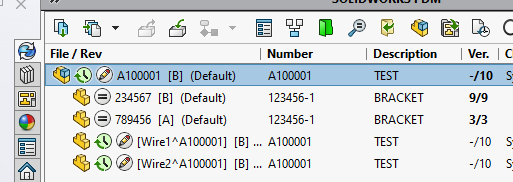

Virtual parts show the “edited but not saved” pencil of death in PDM. Do you use PDM? How do you get around that?

Is this “pencil of death” to which you are referring?

image.png

We’ve had PDM since 2008. We mostly just ignore the edit pencil as it can be futile in large assemblies to have all components fully rebuilt to the point it never shows it. As for virtual components, they share the edit status as the assembly they belong to.

Before saving assembly:

After saving assembly: